Blog : How to automate SSCC pallet labels in a freezing cold room.

Dairy Pallet Labelling

The dairy cold room is a tough environment for both people and automation.

As well, dairy SSCC pallet labels are often complex and need to be applied in places that aren’t always easy to get to.

What kind of equipment will work?

And how do you meet the challenge of getting a suitable machine to work in freezing temperatures?

Here's how we solve typical labelling challenges for the dairy industry:

Variable Placement

Pallets may need labels applied in various locations (front, back, side) and orientations.

No single system seems to accommodate this.

Foodmach Solution:

Put a cobot to work! Integrate a large collaborative robot with a Markem-Imaje label printer.

The label position is adjusted automatically without any input from the operator.

Tough Environment

Equipment struggles to handle temperatures below 4C and liquid condensation.

Foodmach Solution:

Dress for the weather! To ensure performance, we provide systems designed for and proven to work reliably in these environments, year after year.

To ensure reliable label printer performance, we design and build a protective waterproof and heated enclosure with a small footprint.

Complexity

Data on dairy SSCC labels are often complex, with multiple changing variables.

Foodmach Solution:

Use the industry's best software manager.

Integrate Markem-Imaje CoLOS label management software with the dairy WMS software platform, for example, Stackflo, to ensure reliable, repeatable performance.

Accuracy

SSCC labels need to be unique to that pallet, and both labels on the pallet must match.

Foodmach Solution:

Our software takes care of all this for you. The right label will be applied in the right place on the right pallet without you having to lift a finger!

Want to see a Foodmach dairy cold room pallet labelling system in action?

Why choose Foodmach to help you navigate SSCC labelling issues?

All programming and interlocks between the labeller, the labelling software and the cobot are coded in-house by our award-winning technicians. One point of contact for you and a smooth, seamless system (with no unsolvable problems down the track!)

We always include a back-up label printing solution and a barcode label verification solution to guarantee successful labelling on each pallet.

We understand your challenges as a dairy manufacturer. We’ve seen them before, so you can be sure your problem will be handled expertly by our team.

Got a labelling issue you need help with? Let us know!

CoLOS Message Management

Need a better way to ensure that the right code goes onto the right pack?

Even when dealing with multiple pack layers and multiple SKU’s? And at full line speed?

CoLOS will save you a small fortune in time and money.

Need some new tech on your packaging line? Have a chat to us!

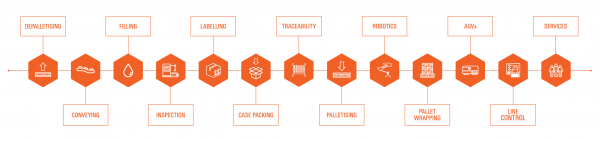

Our sales engineering team will help you work out how to integrate that new machine with your existing equipment.

They’ll also help identify potential issues affecting your future output. Our people make it their business to understand the world’s most innovative packaging technology, so they can also help you choose the best fit for your needs.

Our technicians are so well trained to handle blue-chip brands such as Robopac, Markem-Imaje and ThermoFisher that they can (and do!) step in to replace OEM technicians.

Even better, we provide you with ongoing service and support, so you’re never left holding the baby.

So, if you’re looking for a solution that is guaranteed to work, we’re here to help.

Drop us a line below!